Behind the Wrapper

At KLN Family Brands, we often talk about what we make and why we make it. However, we don’t always discuss how we make what we make. Today, we’re pulling back the curtain and taking a closer look at the process behind our juicy, delicious, and iconic Wiley Wallaby Licorice.

Our Production Expert

Emily Flatau, our Director of Production Support (and formerly our R&D Manager), has been an integral part of the Kenny’s Candy & Confections team for over 12 years. She has an in-depth understanding of every stage of production and is passionate about ensuring that our licorice meets the highest standards of quality and taste. Emily shares her expertise as we walk through the journey of how our licorice is made.

Ingredient Verification

The journey begins long before the first batch of licorice is cooked. All of our ingredients are carefully selected and verified for quality before they are received into our facility. Emily explains, “Our high-quality ingredients are mixed together in a batch of nearly 3,000 lbs. Once the batch is completed, it’s checked for quality before moving on to the next step.”

Quality assurance is an essential part of our process. Since quality and safety are core values at KLN, every batch is tested multiple times throughout production to ensure it meets the highest standards. Each batch undergoes thorough checks to guarantee that it will deliver the delicious taste and texture that our customers love.

Emily adds, “Quality is woven into every step of our process. From the moment the ingredients arrive to when the final product is packed, we ensure that what’s going into every bag is the best possible licorice.”

Cooking the Perfect Batch

Once the ingredients are verified and the batch has passed its quality checks, it’s time to start cooking. During this phase, the licorice mixture is heated to over 250°F to achieve the perfect consistency and flavor. This precise temperature control is critical to making sure that the licorice reaches its ideal chewy texture.

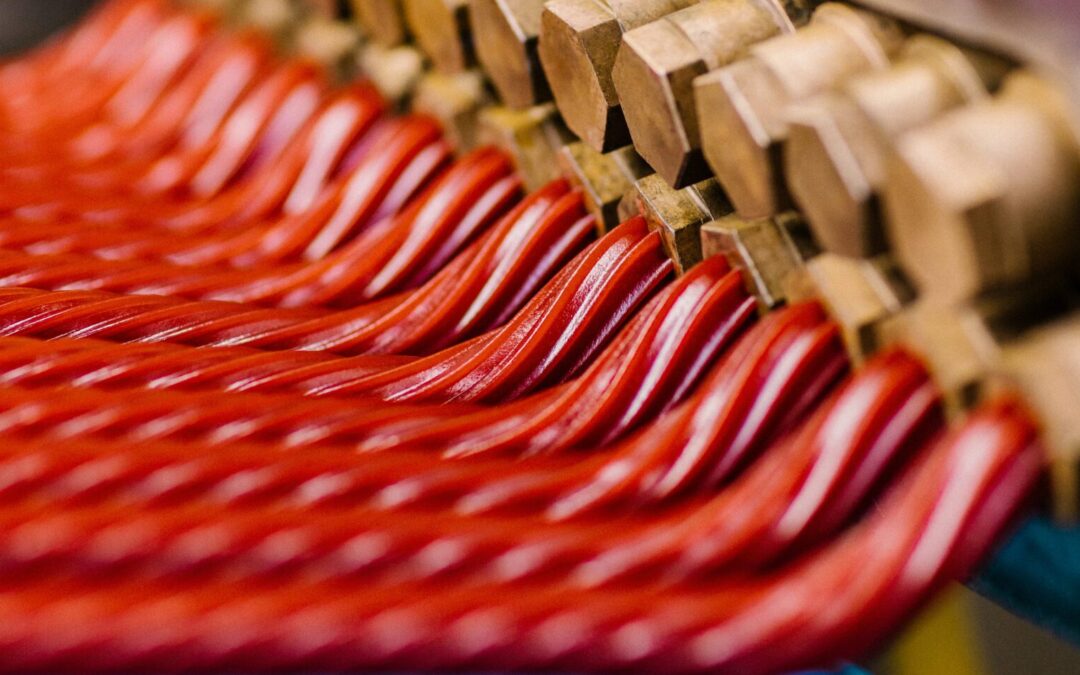

“The cooked licorice is then transferred to an extruder, where it is formed into its iconic shape,” Emily shares. It’s in this step that the licorice takes its familiar twist, ready to be sliced into individual pieces.

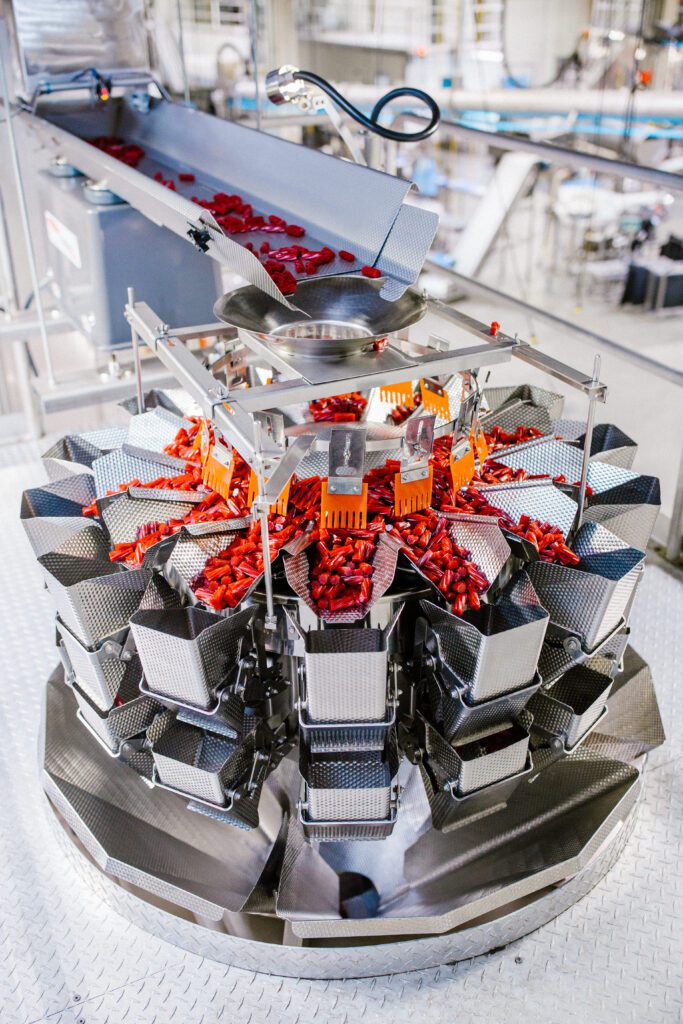

Once the licorice has been extruded into its signature shape, it is carefully cooled down. This step ensures the licorice maintains its perfect chew. After cooling, the long strands are cut into bite-sized pieces. These are then packed into our various bag options, ready to be shipped out to our loyal customers.

The entire process, from start to finish, takes approximately 4 hours. It’s a precise and coordinated effort from all of our production teams to ensure the highest quality product reaches you.

Innovation and Consumer Feedback

At KLN, it’s not just about keeping the classics great; it’s also about innovating and evolving with the times. We understand that consumers’ tastes and preferences can change, and we are always listening.

“We want everyone to enjoy Wiley Wallaby,” says Emily. “When developing new products, we not only consider regulatory updates, but we also listen to consumer feedback and rely on up-to-date marketing information to guide our product launches.”

Whether it’s introducing new flavors or refining existing ones, we are constantly striving to meet the expectations of our customers while staying true to our commitment to quality.

None of this would be possible without our dedicated and talented team. From our production staff to our quality assurance experts, each member plays a critical role in delivering the delicious licorice that so many people love. As Flatau reflects on the incredible contributions of the team, she also wants to share another note: “Thank you to the Nelson family for providing the opportunity to make our classics every day and supporting our growth and innovation from generation to generation.”

As we dive into a new year filled with excitement, we are extremely grateful for our team, the Nelson Family, and our customers.